“So never lose an opportunity of urging a practical beginning, however small, for it is wonderful how often in such matters the mustard-seed germinates and roots itself.”

Florence Nightingale

This week, a video blog post gets postponed. Why? I took a "weekend sabbatical" and took a two day class on hand building sheet metal aircraft parts.

Why? Because I miss getting my hands dirty, I love learning new things, and I wanted some practical knowledge that is only learned on the bench with real

I've seen the volunteer mechanics at

Planes of Fame Air Museum working their craft, and been amazed by how easy the make it look. All the while knowing it's not nearly that easy.

So there I was, standing over a bench, looking at a pile of unformed aluminum parts, countersinks, riveting guns, and pneumatic drill motors, wondering how I was going to "use

those to turn

that into something that looked like a

simple aircraft structure".

|

| My

completed "practice project" is at the top. I'm supposed to turn the

pile of metal into something resembling a wing structure! |

I look around a second, and wonder if this is a good idea after all.

If I run now, no one will ever know. I think for a second.

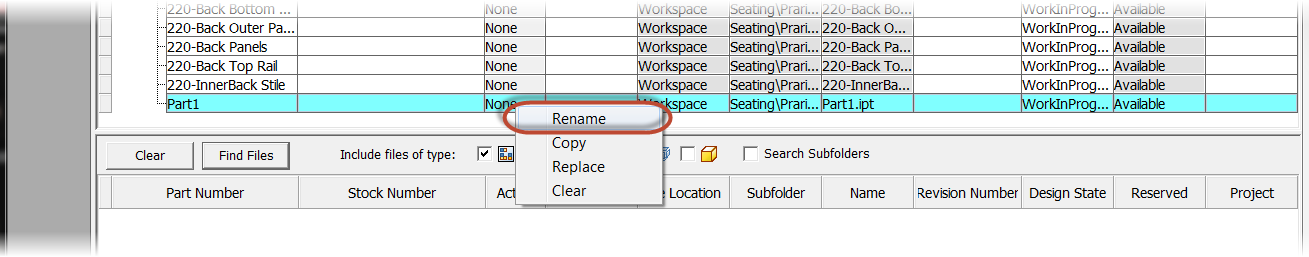

The first day I spent on a "practice part". Just getting the hang of center-punching, drilling countersinking, and riveting.

|

This was my "practice" project. All I did here was get used to the tools. It's partially completed here.

|

The first real life lesson I learned. There's skill that goes into this.

Not that I thought it was a simple task before I tried it. I knew it took skill, but it takes a lot of skill. All those mechanics I saw who made it look easy, are more than mechanics or technicians. They're masters of their craft.

So how did that practice project go?

- I got my holes drilled more or less in a straight line. (Even center-punched, the drill walked a bit),

- The countersinks came out good (redemption!)

- The rivets were more or less correct. (I need to be more diligent about preparation)

I did learn that it's no big deal to center-punch and drill out a rivet though!

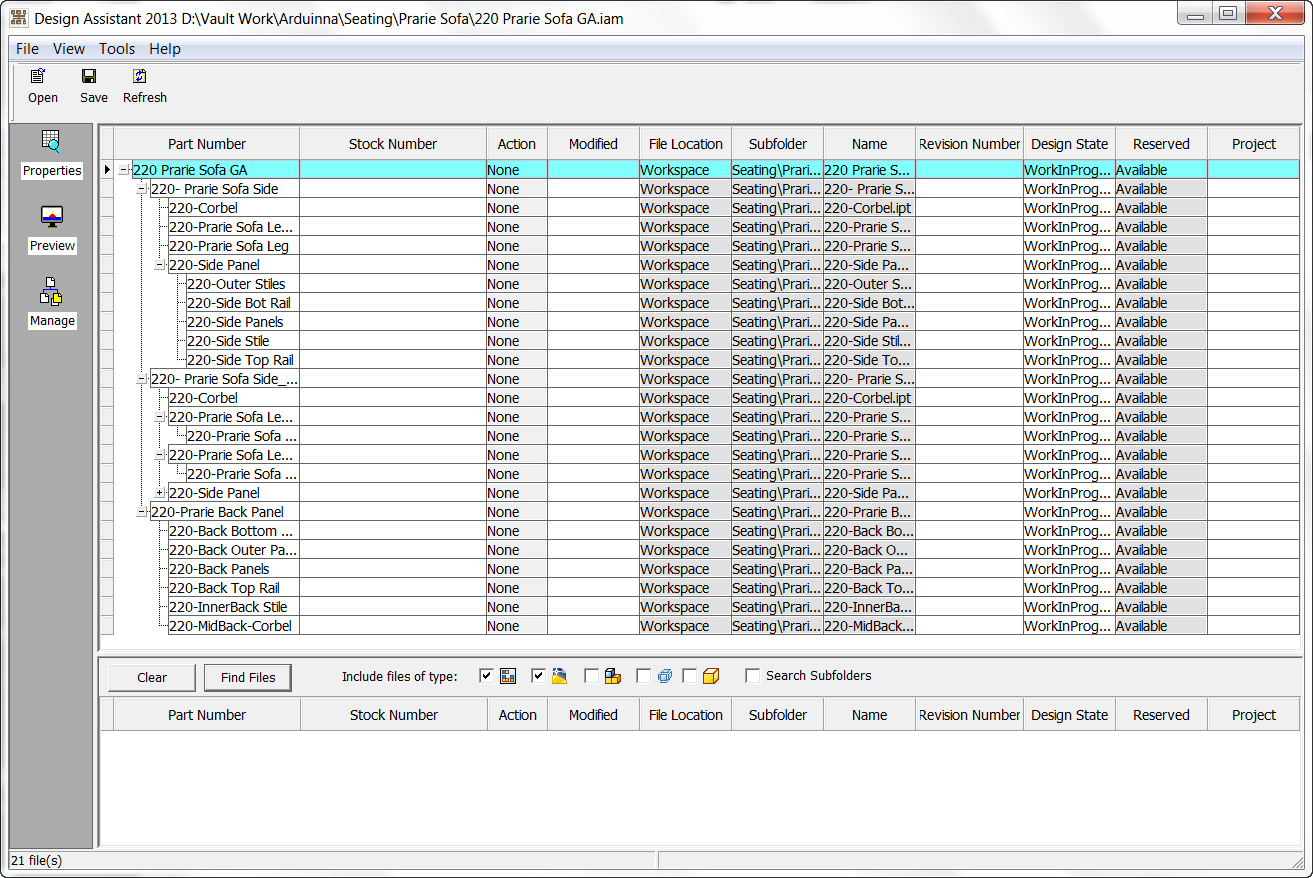

The next day, I had to actually make a basic wing box. I learned how to use a wooden form the ribs from flat sheet.

Then it was more drilling, deburring, countersinking, and riveting.

|

| Beginning the wing box. Cleco pins temporarily hold it together |

And when I say a lot, I mean a lot!

I bucked flat rivets, universal (domed) rivets, I pulled pop rivets.

I drilled, bucked and drilled some more.

|

| The partially assembly wing box with the top skin being attached. |

I learned a lot about how things like this are done. I learned even more about how not to do it!

So in taking the time to do this project what did I learn that I can apply back to my "Computer Aided Design World"?

- For every step I thought I knew about the process, there's some someone who has been around for twenty-some-odd years who knows all the steps I never heard of.

- The term "sweat equity" is something executives use to describe hard work. It's equivalent on the shop floor is "blood, sweat, and tears". Building something with my own hands made me appreciate the value of the latter term. The latter term is far more literal.

- Speaking of blood. When a craftsman of this trade cuts himself, he'll clean the part before getting a Band-Aid, because he knows "blood is corrosive".

- Yes, I cut myself on the edge of an aluminum panel. This doesn't really hurt, but bleeds quiet a bit.

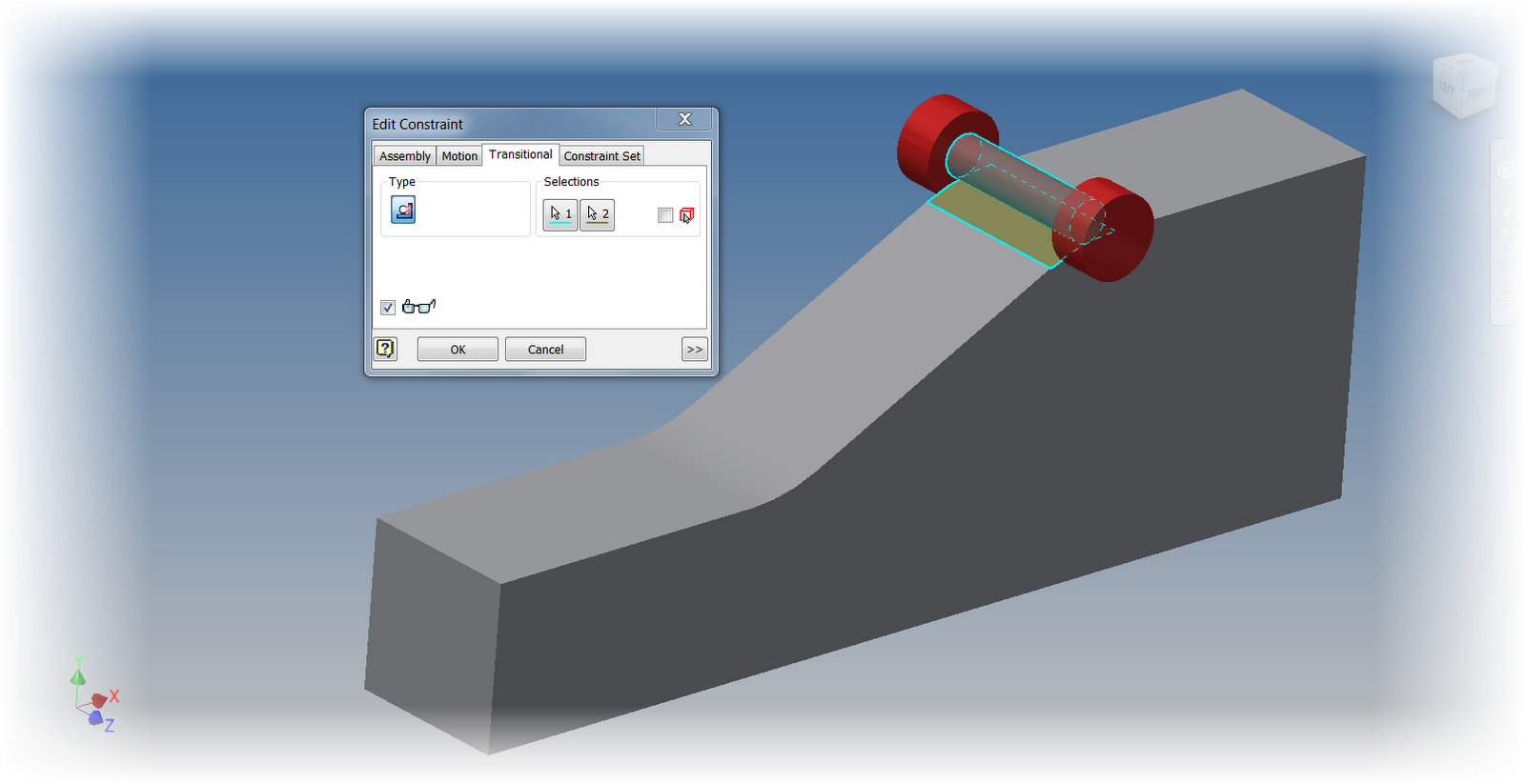

- I also pinched my finger in a Cleco clamp. This bleeds a lot less than the cut. But hurts orders of magnitudes more.

|

| Note: Close one of these on your finger, and it will hurt... a lot! |

So in summary, it was a great experience for me. If anything, I now know what it takes, and what I'd have to learn to be half the craftsman that those mechanics are.

This weekend gave me a new perspective on what it takes to build those designs that come so easily in the computer, and that it would be wise for me to never take that craftsman level of skill for granted.

So I guess the final question? Will I continue, after spending an entire weekend building something that was mediocre at best and busting my knuckles (literally), would I take something like this on again?

Absolutely. And why would I tackle this again?

Because however many mistakes I made, and however ugly that first part came out.

I know I can do better, and I know I can learn more.

And I learned to appreciate the craftsman that make it look so easy.

|

| The completed project. This is the "good" side. Don't even look at the other! |