|

| The engineer print. It's been a while, my friend. |

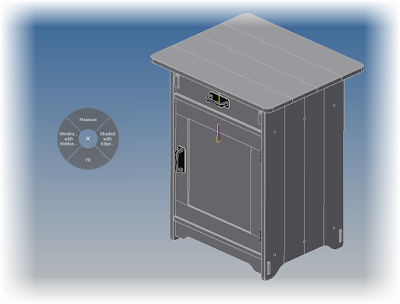

Now, my function is to create designs for material handling equipment using those very same tools. Conveyor lines, in a word or two.

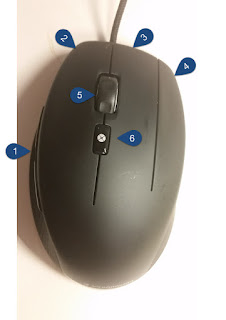

My first steps to "learning the ropes" was helping another engineer create drawings for his project.

And I while I can't say that I was surprised at any one change in particular. The experiences I saw were for the most part, what I expected. Yet, I still found myself reflecting on what I saw during week one.

Here are a few.

I have a desktop, not a laptop!

|

| Well, this is different! |

I've been running Inventor on laptops for over ten years. I've gotten accustomed to just flipping open my laptop at home and running Inventor. Now, when I leave work, I'm done with CAD until the next morning.

That also means that creating Inventor videos for InventorTales is on pause for the moment. I don't currently have the gear. But I am hoping to be able to do that again soon. :)

Change is hard... For a reason.

|

| Changing is one thing. Making the right changes? Another thing entirely. |

I could take a couple of hours to reinstall software if I needed to. It just took a little planning.

Now, I'm exposed to the deeper ramifications to changing things. How does this affect your fellow engineers? Will this "simple" change cause confusion on the shop floor that will cause delays and mistakes?

Change often requires the careful thought of a chess master, not the lightning fast reactions of a table tennis player.

Just because change is hard, it doesn't mean good people are unwilling to make changes.

|

| One thing about change. You can't avoid it. |

Which brings me to my final point...

Know your product!

|

| Remember, tools are what make your product. Good tools should make a better product faster. |

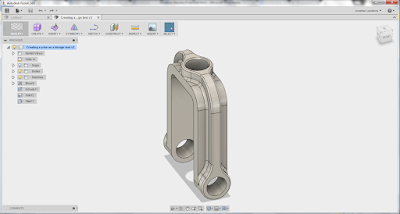

Now.... Surprise! Material handling equipment is the product. Software exists as a vehicle to get that equipment built. It's a tool, just like the laser mill for cutting steel, and the router for cutting plastic.

No matter how cool the tool is, how pretty it works, if it doesn't help get the product made, then it's just a cool parlor trick.

In Conclusion?

First of all, there is no conclusion. This story is still getting written and it will get written for some time to come. I hope to be an asset to my new employer helping them make a better product, and I hope to learn a new set of skills myself.

In one week, I've only taken the very first steps. I hope in the following weeks to keep taking those steps, and to share them with you out in the 'Verse.

Stay tuned!

Photo Credits

photo credit: Rolleiflex TLR on Rollei blueprint at Rollei/DHW factory Braunschweig Germany via photopin (license)

photo credit: Choose Your Direction Sign House Gainesville via photopin (license)

photo credit: Changes #2 (lock) via photopin (license)

photo credit: A Worker at Linread via photopin (license)