|

| A P-51 Mustang at Chino Airport in Southern Californai |

|

| An image of the two separate socket halves |

|

| The Welded Socket |

|

| A P-51 Mustang at Chino Airport in Southern Californai |

|

| An image of the two separate socket halves |

|

| The Welded Socket |

Recently, I had an opportunity to mix some modern technology with the restoration of an 80 year old airplane.

The project is a Bell P-39 Airacobra, which is being restored to be a non-flying display at Planes of Fame Air Museum. One of the tasks I was given was to come up with four faux .030 caliber machine gun barrels for the wing mounts.

|

| An example of a restored P-39 Airacobra By San Diego Air and Space Museum ArchivesUploaded by Bzuk at en.wikipedia - Source, Public Domain, https://commons.wikimedia.org/w/index.php?curid=24375991 |

|

| The P-39 I'm helping with has a little ways to go before its finished! |

All that was needed was a short length four to six inches so it looked like there was a barrel inside the flash suppressor.

Given the tools I had available to me, I opted to 3D print the barrels.

The first step was to get some measurements. Fortunately, Planes of Fame has an SNJ Texan that has a fake 30 caliber machine gun barrel I could use for measurements.

The SNJ and the barrel I could use for measurements.

With measurements sketched on a piece of paper,, I headed home andI created the model I needed in Autodesk Fusion. It wasn't a difficult model. I had it in about an hour or so.

|

| The 3D Model in Autodesk Fusion |

The next step was to print it out. My plan was to print in black PETG, but it didn't arrive before the weekend, so I printed in gray PLA so I would have something to test fit.

|

| The PLA Print in Progress |

Once Saturday rolled around, I had a chance to see how the test barrel fit.

I was pleasantly surprised to see it fit well! It fit perfectly in one flash suppressor, and should go into the other three with a little light sanding.

|

| The 3D printed test part next to its "sample |

|

| The 3D printed part placed in its tube. Its not fully seated here. |

|

| The 3D printed barrel recessed in the tube. This will be its final position. |

The next step? Print in the PETG I intended to, perform another test fit, and make preparations for permanent attachment.

In conclusion, it was a unique experience to be able to be able to use Fusion to create a model that could be 3D printed for the restoration. I'm grateful for the opportunity.

But my part was indeed small, and I'm not the only one creating models that are turning into parts for this restoration.

To see some amazing Inventor work that has turned into real parts for this restoration, check out Aviation CAD Technotes here!

One last bit of "Legal Talk".

Any opinions expressed here are my own, and not necessarily those of Planes of Fame Air Museum.

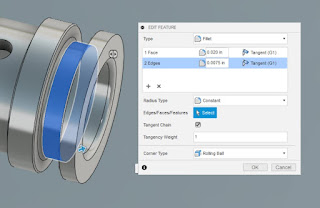

Once upon a time, I was asked, in reference to Autodesk Inventor and Autodesk Fusion 360, "Why would someone want to have a fillet feature with more than one radius in it?"

|

| An example of two different fillet radii in Fusion 360 |

It's a fair question. It's likely we can pick a feature in just about any CAD tool and ask, "Why is that there?"

But to that end, I did have a reason one might want to combine two different fillet radii in one feature.

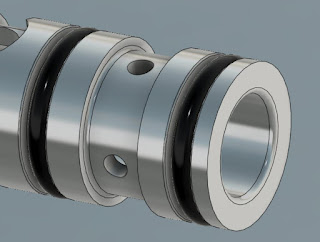

It's a matter of organization. In my design work, I often find myself modeling O-ring grooves, which nearly always have a different radius at the top and the bottom of the gland. Having the ability to combine the different radii in the same feature allows me to combine the fillets into a "O-ring Radius Feature", and maybe shave down the feature tree a little bit.

An O-ring groove using two different radii fillets in the gland.

|

O-rings installed in the glands. Just to give some context to the first image. |

Another case I've used was way back when I was designing sheet metal tooling. I used it when "keying" a rectangular insert. In that example, the opening has 3 radii of one size, and the fourth is a different radius. The insert has chamfers of a similar size. This prevents the insert from being inserted in the wrong direction. Why fillets on the opening and chamfers on the insert? It was easier to machine with the tooling of the time!

|

| An example of a sheet metal stamping insert |

While you might not run into one of these particular examples I've described, maybe there will be something similar that you can use.

Is it life changing? Not very likely. But maybe it's a little food for thought as you make your way through the 3D CAD world.

First, I have to start with my big disclaimer.

While I've had experience with drawing standards, I don't consider myself a full blown expert. There is so much detail in standards, I can't say I'm an authority on all of them.

Also, living in the United States, I work in the ANSI/ASME standards.

My apologies to those who are living the ISO life (which is basically everyone who isn't the United States), I'm only acquainted with that standard.

So this post will be based on "freedom units", that is feet, inches, and bald eagles.

Joking aside, I hope this post is entertaining at least. Onward to the post.

My current place of employment has a lot of legacy drawings. It's not uncommon to find a scanned drawing from the 1970s in our data management system.

It's like digital archeology!

One of the things I find can be a big challenge, and very interesting, is interpreting dimensions, notes, and callouts that have fallen out of favor over the years.

Recently I was part of a discussion regarding a hole callout on one of these old drawings.

The callout stated "Drill" and called out a specific drill size. In the case of the screen capture shown below, the drill size called out is a #30 drill, which is .1285 inches in diameter. But even the diameter is called out as a reference dimension.

The really interesting thing about this callout is that it implies it's own tolerance, in accordance with AND10387.

The tolerances are based on the size of the drill, and a screen capture is shown here from Engineers Edge. You can even see that it has a link to AND10387

But now comes a plot twist.

According to Everyspec, AND10387 was cancelled for new design and is only used for "replacement purposes". No new standard is shown to supersede this one.

So what does that mean?

I wasn't able to find a specific standard that states specifically how to handle drilled holes now. But my experience has taught me that, if required, a tolerance will be implicitly stated next to the dimension. If no tolerance is stated with the dimension, then the block tolerance will be used.

A hole with the tolerance implicitly stated

Since AND10387 is only valid only for replacements, there's a good chance you may never see a drawing with an implied drill tolerance. But there's always a chance an old drawing will rise from the depths. So perhaps it's a good reference to keep in the archives!

And if anyone is aware of a standard that calls out standard drill tolerances, or if you just "do it another way", feel free to leave a comment.

Sometimes, a lesson learned from long ago comes to pass.

Recently I was working on a project that required I transfer the location of four threaded holes to a piece of aluminum so clearance holes could be drilled. The question was, how to do it?

Sure I could measure out the holes, but the threaded holes were t-nuts pressed into plywood, and the holes for the t-nuts were measured using a tape measure. So the hole placement was made to more of a carpentry accuracy than an aerospace tolerance. But I still wanted to keep the clearance holes as tight as practical.

|

| A 3D model of the T-nut that was pressed into Plywood |

But I remembered watching an old tool maker when I was a young engineer fresh out of college. And if you haven't guessed by the title of this post, that was about 25 years ago.... Ouch.

He showed me a "threaded hole transfer punch". It's a small tool that stores threaded screws that look almost like set screws. However they have points in them instead of the hex that one would expect from a set screw.

I had my solution! I placed an order with McMaster Carr for the punch I needed, and I had it in my hands the next day.

They're screwed into the holes you need to transfer. You then position the workpiece that requires the holes, give it a quick strike with a hammer. And now you have marks where you need to drill.

Then it's off to the drill press to drill the holes you need.

|

| The transfer punch tool and two of its inserts. The inserts are stored inside the tool. The tool also doubles as a wrench for the inserts. |

|

| The transfer punch with two punches threaded into the T-nuts |

|

| The marks left in the aluminum from the punches. I'm afraid I didn't get a chance to get a picture of the drilled holes. |

Using the tool that old die maker showed me, in the way he showed me how to use it, I had the holes I needed in no time flat. The whole process took about fifteen minutes. And that includes walking to another building where the drill press was kept!

That's a lot quicker than trying to match the holes by measuring it out.

And, in a strange case of deja vu, a young intern looked over my shoulder and asked me, "How did you mark those holes?"

So it was my turn to pass along the lesson I learned 25 years ago from an old die maker about the "threaded hole transfer punch".

Other than sharing a cool story, what's the lesson?

I would say to look for those small mentoring moments that can sometimes come from the most unexpected places. It might be from someone on the shop floor, an analyst in the corner of that dark office, or a program manager who's "been there and done that".

A lesson can be learned in a few minutes can take years to pay off. But when it does, it can be a life saver!

Wow, that lesson was twenty five years ago.... Thinking of that I'm suddenly overcome by the urge to yell at some kids to get off my lawn....

About the Author:

Jonathan Landeros is a degreed Mechanical Engineer and certified Aircraft Maintenance Techncian. He designs in Autodesk Inventor at work, and Autodesk Fusion 360 for home projects.

For fun he cycles, snowboards, and turns wrenches on aircraft.

But some time ago, someone asked me, "Have you ever run a Stress Analysis Simulation on one of those parts?"

It seemed like an interesting challenge. What would a part designed in the 1940s look like when tested with a modern Finite Element Analysis (FEA) tool.

So I decided to fire up the Simulation module in Fusion 360, and set up a stress test to see how a component I'd modeled would hold up.

The part I decided to use was for a P-51 Mustang, made by North American Aviation.

The part itself is the body for a "Hydraulic Landing Gear Uplock Timing Valve". I decided I'd see how Fusion 360's simulation tools would analyze this old component.

First, I set the material. The print listed the material as "24ST", which is a designation now obsolete. However the new equivalent is 2024. So I created that material in Fusion 360's material library, and applied it to the part.

|

| An excerpt from the print. The 24ST aluminum bar can be seen in the material column |

First, I needed to figure out what pressure I would be testing for. Based on the document I found here, the P-51 has a "low pressure 1000psi system". That comes out to about 69 bar in the metric system.

For my test, I'll double that by applying a pressure of 2000 psi (138 bar). I'm using that as my burst pressure for this housing.

As for fixing the part, I used the two mounting holes in the housing.

With all that said and done, it was time to fire the simulation off into the cloud and wait for the results.

All I can say that in the engineering parlance, I'd call this part "hella strong". Even at double the expected operating pressure, the minimum safety factor is about 4.5!

Assuming my analysis setup is good, the part is probably overbuilt and could be optimized to save weight.

So why didn't the engineers at North American spend more time reducing weight?

That I can only speculate on.

But there are some things to consider. The body was created without the benefit of simulation tools. Add the fact North American Aviation was designing this aircraft in the middle of a war, one can probably see how not every part is optimized as much as it could be.

Add to that, the part measures about 3in x 1-1/8in x 1-5/16in (76mm x 29mm x 33mm), Even though weight is important in aircraft, optimizing this part probably wasn't a high priority considering it's small size.

So there we have it! A P-51 Mustang part analyzed in Fusion 360. It was a fun exercise to see what stresses on this part would look like when analyzed on a modern tool!

Happy modeling!

Jon

Acknowledgements:

P-51 Mustang print available from AirCorps Library

P-51 Mustang picture takien at Planes of Fame Air Museum

|

| Part of a Hydraulic Valve for a P-51 Mustang |

|

| A hydraulic housing in the Fusion 360 mobile viewer |

|

| A portion of the original print used to create the model. |

But a few weeks ago, I had a fantastic opportunity to create a model that would be used to make a part for the restoration of a B-17 Flying Fortress.

The part was a "friction washer" for use in the throttle quadrant. And the team needed geometry that could be cut on a water jet.

It started with a reproduction of the original Boeing print. Having the original dimensions made the modeling easy. It was interesting to note that even though standards have changed in the nearly 80 years since that print was created, it's not too different from the prints I work with today.

|

| The model of the friction washer, created in Fusion 360 |

Next, was to place the view on a drawing. The first goal was to dimension the drawing as a way of verifying all the dimensions were correct. Second, the drawing is what creates the 2D DXF file for the water jet.

Once the drawing is created, delete any information that isn't required for the waterjet. This includes borders, title blocks, dimensions, centerlines and centermarks, etc. You might even consider creating a second page in the drawing for this purpose.

Also, make sure to save the drawing before you export. I learned the hard way when I realized that the first file I exported still had all that extra geometry. Save the file before export!

|

| The dxf geometry sent to the waterjet |

Once I recovered from my snag. I sent the files off to my colleague for cutting.

A few days later, we had our part and it fit perfectly, making for a very satisfying little journey.

And while this little project was well worth a victory lap, there were three minor challenges that are worth mentioning.

1) Drawing standards have changed over the decades, and while the drawing wasn't hard to interpret, some information wasn't where I'd expect it to be. Modern 3D modelers have spoiled us. We can "slap down" a new view in seconds. For the drafters of old? Adding the simplest view would take minutes. A more complicated one? Hours.

The number of views was kept to a minimum. A part of single thickness, such as this one, will likely have the thickness dimension called out in a note.

2) Not only have drawing standards changed, industry standards have changed. That material specification called out in 1943? It's been long superseded by a new standard. It's even possible that the standard that superseded the 1943 standard has, in turn, been superseded itself.

Be prepared to spend a few minutes Googling the updated standards. Thank goodness for the internet!

3) Finally, how does one interpret the tolerances called out on the drawing? Symmetric, +/-.005 for example, is easy. Model to the nominal. But what about a tolerance such as +.010/-.000? Do you "split the difference"? Do you aim for nominal?

In my case, I decided to aim for the dimension as it was called out on the print. I figured that was the target dimension, after all.

And in my case. It worked! Fusion 360 gave me an excellent dxf file that the waterjet used with no issuee, and the part fit perfectly into its intended position.

It was a wonderful opportunity to contribute to a restoration. And a wonderful learning opportunity!

Acknowledgements

Print Reproduction via my Aircorps Library Subscription

Models and drawings created in Autodesk Fusion 360

|

| A sample of a different PLA print. Usually a great material to work with. Sorry, the actual print is proprietary. |

|

| The Z setting adjustment in my slicer. I moved the nozzle slightly closer to the bed. |

About the Author:

Jonathan Landeros is a degreed Mechanical Engineer and certified Aircraft Maintenance Techncian. He designs in Autodesk Inventor at work, and Autodesk Fusion 360 for home projects.

For fun he cycles, snowboards, and turns wrenches on aircraft.

I've spent just over 20 years working with 3D CAD programs. That experience has been nearly exclusively with the Autodesk manufacturing product line, starting with Mechanical Desktop (shortly after the earth cooled), and followed by Autodesk Inventor.

|

| We've all seen the ubiquitous, 3D model, floating in space. |

That experiment, unfortunately, failed. Siemens NX, while a good program, wasn't the right program for the needs of my employer.

A few months ago, my company announced that we would be going to Solidworks.

Other than dabbling in it a few times, I've never touched Solidworks. This could be an enormous change for me.

Or not, perhaps?

|

| CAD Tools - Is it just a Virtual Toolbox? |

I completed an abridged "transfer training", where we were shown where all the buttons were and how Solidworks ticks. After that, we were released upon the world.

And what did I find? Were my eyes opened to a brand new world? Was Solidworks so much better that I wondered what I was missing?

Did I wail and gnash my teeth because Inventor was far better and I was being forced to use this inferior product?

No. I left that training and thought, "Wow! They're really similar."

Sure, Solidworks has an Extrude and and Extrude Cut button, while Inventor has the same options combined within one Extrude command. But they both add and remove material in the end.

There's functions where I think Inventor has it down better, and others where I have to give it to Solidworks.

In the end, I see it as an opportunity to learn a new skill, enrichen myself, and be more marketable in a competitive world. I think that's going to take me further in the long run.

So I suppose the point of my writing this is to muse about how CAD programs are tools. They're not the endgame, there the means to create our designs, drawings, and help us build our products.

And there's nothing wrong with learning a new set of tools. It can only make me a more marketable designer.

One Final Note.

If you're using Fusion 360, you can change your Pan, Zoom, Orbit shortcuts to reflect Inventor or Solidworks, among other programs?

I've switched mine to Solidworks, it may not be the same as having Solidworks at home, but it does makes it easier when I switch from one to the other at work!

|

| The Pan, Zoom, and Orbit options in Fusion 360 |

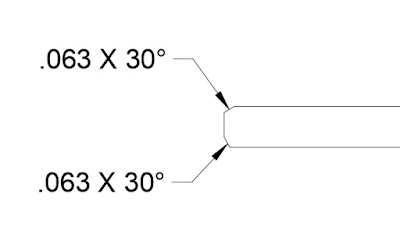

Many CAD tools contain a chamfer note that I would describe as a leader style.

You've probably seen it, probably used it even.

It utilizes a leader to point at the chamfer, and contains both the chamfer distance, and angle in one simple note.

The advantage of this style is it's compact, easy to read, and especially easy to place when the chamfer is packed into a crowd with other nearby dimensions.

But this dimensioning style as a subtle disadvantage. This style of dimension doesn't identify the direction of the chamfer. So if the chamfer angle is something other than 45 degrees, the angle direction is open to interpretation.

|

| Even though the chamfers are different, the callout is is the same. It's also correct in both cases. |

That literally means that a chamfer in either dimension meets the print. That can cause confusion, and possibly "heated debates" when a parts acceptance or rejection hangs in the balance.

The other option is to call out the chamfer distance and angle as separate, distinct dimensions. This identifies the direction of the chamfer much more clearly.

Of course everything is a trade off, and this method does take a little more room on the page than the leader style. Even on the image above, you can see that the page is a bit more cluttered, and someitmes a detail view is required to ensure all dimensions can be clearly seen.

In the end, I find I use both. The leader style is used for 45 degree chamfers, since there isn't really an angle direction to speak of. However, when the chamfer is an angle other than 45 degrees, it's time to employ the explicit style, and make sure the direction is clearly shown.

Ultimately, it's up to you which chamfer style you use. Perhaps you have the advantage of tribal knowledge to correctly identify these features. Or you have other means to make sure the chamfer is cut the correct way.

If anything, this is a good practice hailing from the time when "back to the drawing board" was a much more literal statement!

About the Author:

Jonathan Landeros is a degreed Mechanical Engineer and certified Aircraft Maintenance Techncian. He designs in Autodesk Inventor at work, and Autodesk Fusion 360 for home projects.

For fun he cycles, snowboards, and turns wrenches on aircraft.