Eighteen months ago, I took on the task of running the 3D printer at work. It's a

Fusion3 F400-S, similar to the upgraded 410 shown on Fusion3's website.

It's a FDM (Fused Deposition Modeling) printer, in other words, it melts plastic and lays it down one layer at a time until it produces the desired result. '

At least that's what's supposed to happen!

All I can say is that it's been fun, frustrating, rewarding, and discouraging at various stages of the journey. I've tasted the sweet joys of victory, and I've muttered the bitter "F-Bomb" of defeat.

Most of all, I've realized that while I've learned a lot, I'm far from an expert. Because of that, I'm not going to tell you how to make a successful print. There are plenty of people who are doing that, and frankly, they are much more knowledgeable than I.

But what I can share are my experiences watching our 3D printer making an impact in our design process. So here I go, showing a few places where having a 3D Printer has shown itself to be a helpful part of our design processes.

One disclaimer before I get started. I can't share the real parts online. Words like "proprietary" and "security" start getting thrown around. So I have to use "surrogate" parts that represent the concept.

Thanks in advance for bearing with me!

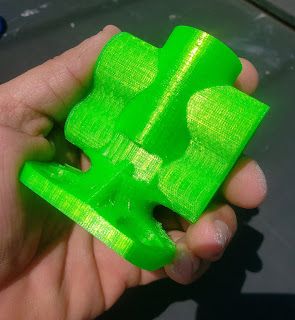

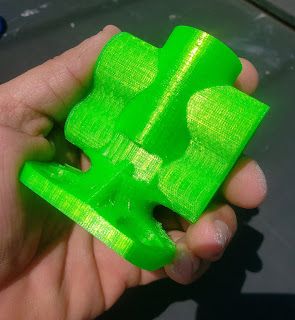

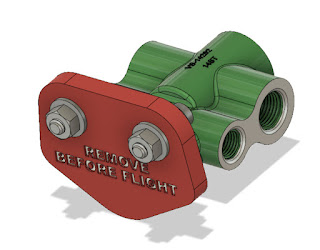

1) The "Show and Tell"

|

There's nothing like holding a represenation

of the part in your hand. |

When I think of 3D printing, this is the first application that comes to my mind. It's simply a cosmetic print meant to give an idea of the "form and function" of the part. In our case, it didn't do anything but give everyone a sense of size and shape.

This might seem simple at first. With 3D CAD Modeling tools, we can model our designs precisely. So why "waste time" printing a part that's just "for looking".

Well, I know I've fallen victim to being able to zoom into a small screw until it looks like a table leg. And with that, comes a distortion of scale that can affect those of us that live in the real world.

And I know I'm not the only one. I've heard more than one person say, "I really didn't think about big/small that part is!"

A particular example comes to mind. I was in a meeting where the projected image of the CAD model rotating on the wall was completely ignored because engineers and customers were drawn to the 3D printed model that represented a much more tactile experience that couldn't be experienced with the 3D model.

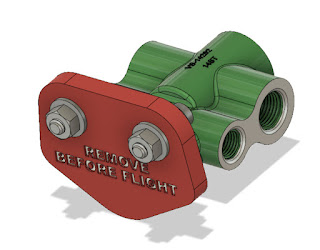

2) The "Assembly Test"

This print is in reality a series of parts that make up an assembly. It may even be a combination of real and printed parts.

|

| A sample part with a real hydraulic fitting threaded into one hole |

The purpose of this part is to ensure that the parts you've carefully designed can not only be put together, but put together easily.

|

| I can see which fitting will have to get torqued in first! |

For example, can a bolt be inserted into the bolt hole, and once in there, can the wrench follow up and turn the bolt once it's in the hole.

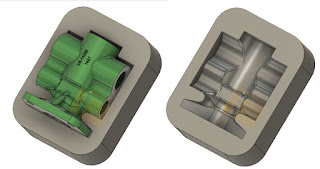

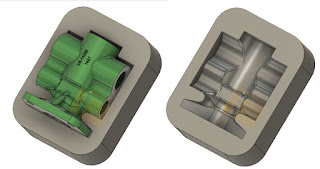

3) Tooling and Covers

I've lumped these tooling and protective covers into the same category, partially because the two sometimes blend into each other, at least where I work.

|

| An example of a protective cover that has a unique shape |

Because the 3D CAD model exists, it can be relatively quick to create a negative of the part, then print that negative as quickly as a few hours.

|

An example of a cradle created by creating

a negative of the part. |

Sometimes these shapes are odd or unique, and can't be easily duplicated by the machine shop, or frankly, the machine shop just doesn't have the time to make them.

In any case, 3D printing provided us with the ability to create odd geometry quickly, without disrupting other operations.

In Conclusion

My intention here was just to share a few cases where I've found 3D printing helpful. By no means is it comprehensive. If anything, I hope it provides a few ideas, and dare I say, inspiration.

I think it's also important that we bear in mind that 3D printing is a new tool that can supplement existing tools. Don't by a 3D printer thinking that you'll be able to shut down your machine shop, woodshop, or welding shop. .

So take these ideas and make them you're own. And feel free to share in a comment if you have a good use for 3D printing in your home or office.

Acknowledgements