This page is a collection of various helpful tips I've collected during my travels. While not always flashy, they are solid little tips that make the day to day grind go by a little easier.

It's designed for somebody to browse through and "cherry pick" the ones they like. So take a few minutes and take a look!

Where applicable, I've also added links to more "in depth" descriptions. So if you want more info, there's more to be found!

Enjoy!

Jon Landeros

Autodesk Inventor Part Modeling

- Is a part too large to e-mail? Dragging the End of Part marker to the top of the tree will reduce its file size. (Added 23-Nov-2011)

|

| End of Part marker at top of tree. |

- When entering dimensions, typing "Parameter_Name = X.XXX" will create the dimension, and name the parameter.

|

| Renaming a parameter |

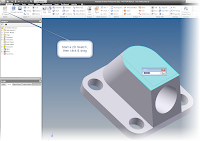

- An offset workplane and sketch can be created at the same time. Just start a sketch, then click and drag from the desired face.

|

| Offset workplane & sketch in progress |

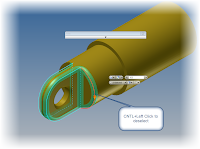

- If you're picking several objects, CTRL+Left Click can deselect the object without exiting the command.

|

| Using CTRL+Left click to deselect a fillet edge |

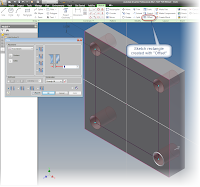

- Use "Offset" to create four hole patterns that are easy to create and adjust

|

| Offset used to locate four, evenly spaced holes |

- The tables for threaded and clearance holes are editable. Values can be changed and new sets of holes can be added. Paul Munford has a great set of instructions in his article posted here!

- Inventor sheet metal comes with a default K-Factor (bend allowance) for unfolding sheet metal, but how do you calculate your own K-Factor? Check out this article from Design and Motion here!

Autodesk Inventor Assembly Modeling

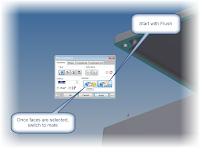

- When mating narrow faces, use the Flush constraint to select the faces, then switch to mate to finish the constraint. Hint: The picks are easier! (Added 23-Nov-2011)

|

| Using the Flush constraint to select the faces |

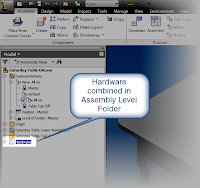

- Use Assembly Level folders to help organize components in your assembly browser

|

| Assembly folder used to organize hardware |

- If you want to see all your constraints in one place in your browser, switch from "Assembly View" to "Model View"

|

Toggling between Assembly View & Model View

|

Autodesk Inventor Drawings

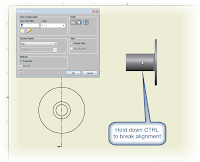

- If you want to place a section view while simultaneously breaking its alignment, hold down the control key. Added 23- Nov-2011 (Thanks Johan of Design by Inventor)

|

| Breaking the Alignment with the CTRL key |

Thanks for the short cuts I use both 2014 and 2015 Educational versions

ReplyDelete